Font Size:

NCR paper coatings refer to CB coatings and CF coatings. CB coatings are mainly composed of microcapsules, spacers, adhesives, etc.; CF coatings are mainly composed of color developers, fillers, adhesives, and additives. Therefore, the main factor affecting the quality of CB coatings is the quality and dosage of microcapsules, and the main factor affecting the quality of CF coatings is the quality and dosage of the developer.

The solid content of microcapsules is generally 40%-50%, mainly composed of colorless dyes, wall materials, and emulsifiers. The quality of microcapsules mainly affects the quality of CB coatings. Excellent microcapsules must have the following points:

① The shell is uniform, and the colorless dye oil should be completely wrapped.

② Moderate particle size and physical strength.

③The shell is impermeable.

④ storage stability.

⑤ High concentration but low viscosity.

The colorless dye oil is made by dissolving the colorless dyes CVL (Crystal Violet Lactone) and BLMB (Benzyl Methylene Blue) in solvent oil, but due to the paper coated with BLMB capsules, it will appear blue after some time, so it now been replaced by SRBP (diaryl carbazole methane). CVL has strong color development ability and fast speed, but poor light fastness, while BLMB or SRBP has slow color development speed, but after color development, it is not easy to fade. Therefore, in actual production, the two raw materials are usually mixed and used. The particle size of the microcapsules also has an impact. If the particle size is too large, it is easy to break, and the pollution of the paper is also great. In severe cases, it may even affect the use. However, if the particle size is too small, the strength of the capsule is high, which will affect the color rendering effect.

In CB coatings, microcapsules generally account for 30%-60%. The more microcapsules added to CB materials, the better the color rendering effect, but the greater the production cost and paper pollution. To reduce production costs, generally, the amount of CB coating microcapsules used on the upper page will be relatively low, because the upper page only needs to ensure that the color rendering effect of the second paper is not bad. However, the microcapsules in the CB coating formula of medium-page paper use a higher ratio to meet the color rendering requirements of carbonless copy paper. Of course, if we can adjust the proportion of CB coating microcapsules in the middle page according to the different brochures matched by different customers, the production cost will be more effectively controlled.

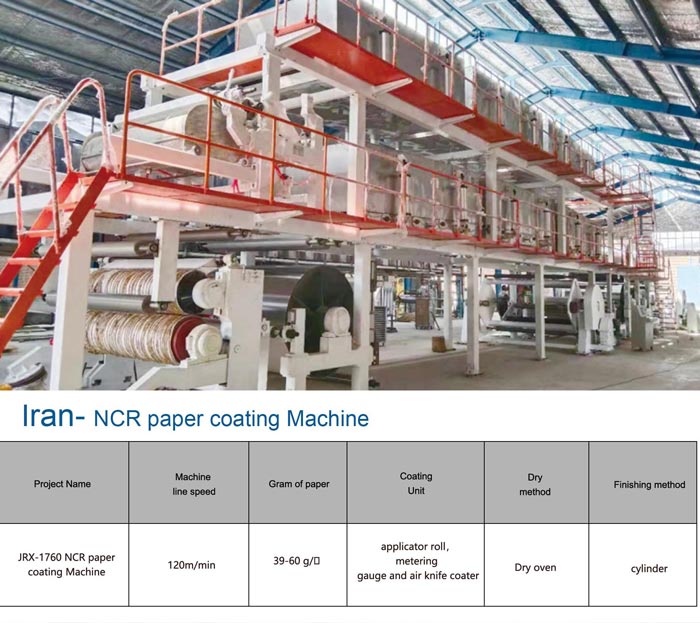

What is the thermal paper coating machine line?

2018-03-14Why does the thermal paper coating machine request calender?

2018-03-14Lubricant in paper coating chemicals

2018-03-14SBR latex using in paper coating industry

2018-03-142023 Whiteboard Paper Market Analysis: Fluctuations and Recovery

2018-03-14