Font Size:

Carbonless copy paper is a kind of copy paper that relies on the reaction of chemical materials (colorless dye and color developer) to achieve color rendering. color.

Carbonless copy paper is divided into five types: top sheet (CB), middle sheet (CFB), bottom sheet (CF), single-function self-induction paper (SC) and dual-function self-induction paper (SCB).

Carbonless copy paper is divided into blue printing paper, black printing paper or other color printing paper according to the color rendering.

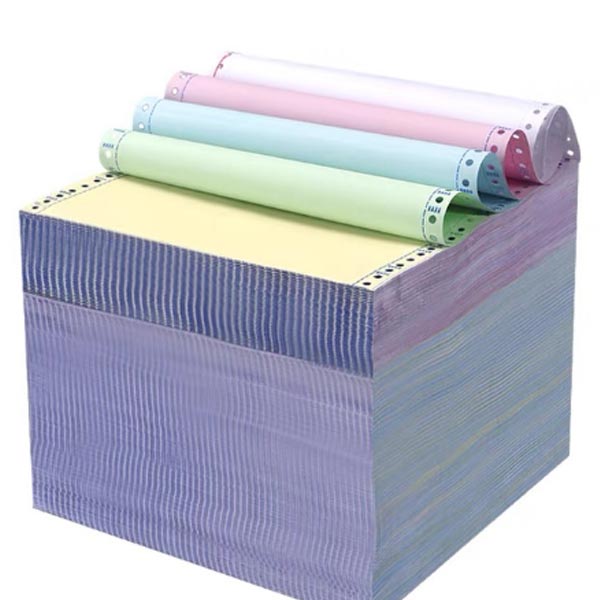

Carbonless copy paper is divided into five types: red, yellow, blue, green and white.

Carbonless copy paper is divided into grade one, grade two and grade three according to the quality.

Carbonless copy paper is divided into ordinary type and light fastness type according to light fastness.

Carbonless copy paper can be divided into flat paper and roll paper according to the specifications: The common size of flat paper is 787mm×1092 mm, which is called positive paper, and the corresponding size is 889mm×1194mm, called large paper. Other sizes can be customized. The commonly used sizes of roll paper are 381mm, 241mm, 190mm in width, and the length is between 4000m and 6500m. Other widths can be customized. Carbonless Copy Paper Product Introduction

CB paper: The back is coated with coloring agent (back coating), and it is used as the upper layer of carbonless copy paper.

CFB paper: coated with developer on the front and developer on the back (coated on both sides), used as the middle layer of carbonless copy paper.

CF paper: coated with color developer on the front side (front side coating), used as the lower layer of carbonless copy paper.

SC paper: The front side is coated with color developer and color developer (front side coating), and it is used as the upper layer of carbonless copy paper.

Carbonless copy paper can be divided into two types: other color development and self-development color. The most used is other color development carbonless copy paper, which is generally composed of three paper sheets, namely upper paper, middle paper and lower paper. Carbonless Copy Paper (CCP for short), the structure of which is shown in Figure 1.

Upper paper is also called back-coated paper (code name CB, that is, Coated Back), the back of the paper is coated with microcapsules containing Limin pigment oil; middle paper is also called front and back double coated paper (code name CFB, that is, Coated Front and Back), The front side of the paper is coated with color developer, and the back is coated with microcapsules containing Limin pigment oil; the lower paper is also called surface-coated paper (code name CF, that is, Coated Front), and the paper surface is only coated with color developer. Self-coloring paper (codenamed SC, or Self-Contained) is coated with a microcapsule layer containing Limin pigment oil on the back of the paper, and coated with a color developer and microcapsules containing Limin pigment oil on the front.

There are two types of coatings in carbonless copy paper: a CF layer containing a chromogenic agent and a CB layer containing a chromogenic agent. The chromogenic agent is a special colorless dye that has been dissolved in non-volatile carrier oil and encapsulated by microcapsules of 3-7 μm. The impact pressure of forceful writing and printing can crush the microcapsules, allowing the colorless dye solution to flow out and contact the color developer, and a chemical reaction occurs to present colored graphics, thereby achieving the purpose of copying. Carbonless copy paper is divided into 45g/m2CB paper, 47g/m2CF paper and 52g/m2CFB paper according to the quantity; according to the color of the paper, there are five kinds of red, yellow, green, blue, and white; according to the color traces, there are blue, Yellow, orange, black, red and other colors.

This is a carbonless copy paper,

Carbonless copy paper can be divided into two types: other color development and self-development color. The most used is other color development carbonless copy paper, which is generally composed of three paper sheets, namely upper paper, middle paper and lower paper. Carbonless Copy Paper (CCP for short), the structure of which is shown in Figure 1.

Upper paper is also called back-coated paper (code name CB, that is, Coated Back), the back of the paper is coated with microcapsules containing Limin pigment oil; middle paper is also called front and back double coated paper (code name CFB, that is, Coated Front and Back), The front side of the paper is coated with color developer, and the back is coated with microcapsules containing Limin pigment oil; the lower paper is also called surface-coated paper (code name CF, that is, Coated Front), and the paper surface is only coated with color developer. Self-coloring paper (codenamed SC, or Self-Contained) is coated with a microcapsule layer containing Limin pigment oil on the back of the paper, and coated with a color developer and microcapsules containing Limin pigment oil on the front.

There are two types of coatings in carbonless copy paper: a CF layer containing a chromogenic agent and a CB layer containing a chromogenic agent. The chromogenic agent is a special colorless dye that has been dissolved in non-volatile carrier oil and encapsulated by microcapsules of 3-7 μm. The impact pressure of forceful writing and printing can crush the microcapsules, allowing the colorless dye solution to flow out and contact the color developer, and a chemical reaction occurs to present colored graphics, thereby achieving the purpose of copying. Carbonless copy paper is divided into 45g/m2CB paper, 47g/m2CF paper and 52g/m2CFB paper according to the quantity; according to the color of the paper, there are five kinds of red, yellow, green, blue, and white; according to the color traces, there are blue, Yellow, orange, black, red and other colors.

Carbonless copy paper does not need to use wax-coated copy paper. When multiple pages of carbonless copy paper are stacked together, multiple copies of the document can be copied directly by printing or writing. Not only is it convenient and clean, but it can also be made into perforated blank computer printing paper to realize efficient continuous printing and copying.

The reason why carbonless copy paper can be copied without wax-coated copy paper is because it is coated with chemicals.

Carbonless copy paper is divided into upper page, middle page and lower page. On the lower side of the upper and middle pages, a certain chemical is coated, and on the upper side of the middle and lower pages, another chemical is coated. After the combination of the upper page, the middle page (or until there are 6 pages), and the lower page, when the impact force of the printing needle or the pressure of the pen tip is received, the two different drugs will meet and show the color, so as to realize the duplication Purpose.

The upper page is customarily called CB paper, which is only coated with CB drugs on the lower side and is called the CB side; the lower page is usually called CF paper, which is only coated with CF drugs on the upper side and is called the CF side; The page paper is customarily called CFB paper, the upper side is painted as the CF side, and the lower side is painted as the CB side.

CB medicine is a coating containing capsules, binders and additives. The particle size of the capsule is only 3-7цm, the shell is made of resin, and the inside is wrapped with solvent oil, which contains leuco dye. When the capsule is destroyed by external force, the dye oil will flow out. If the CB surface is attached to the CF surface at this time, the dye oil will flow to the CF surface to make the CF medicine stand out.

CF medicines are coatings containing color developers, binders, and additives. The color developers are mainly certain resins and activated clay.

The principle of carbonless paper

2023-11-07Paper chemicals - detailed analysis of defoamers

2023-11-07Surface Sizing Process Affecting Moisture Resistance of Packaging Paper

2023-11-07Introduction of thermal & pressure sensitive dyes-ODB-2

2023-11-07What are the types of coated paper?

2023-11-07The principle of carbonless paper

2023-11-07Paper chemicals - detailed analysis of defoamers

2023-11-07Surface Sizing Process Affecting Moisture Resistance of Packaging Paper

2023-11-07Introduction of thermal & pressure sensitive dyes-ODB-2

2023-11-07What are the types of coated paper?

2023-11-07